Prefab

How Oude Hengel is Transforming Timber Construction with Digital Innovation

Oude Hengel transformed their timber construction process by implementing a configure-to-order solution from Packhunt for Factories. This full-process digital solution, covering everything from sales to production, automates design, pricing, and production-ready outputs for timber buildings, boosting efficiency and reducing errors.

Oude Hengel

More than 100 years ago, Oude Hengel started as a small windmill-powered business in Ootmarsum. Passed down through generations, the company grew into a leader in timber construction, blending tradition with a drive for innovation. Today, under Valentijn Oude Hengel’s leadership, they are taking their legacy further, embarking on a digital transformation journey to stay ahead in a rapidly changing industry. With Packhunt for Factories, Oude Hengel set out to bring something completely new to the customers: order full timber constructions in minutes and with unmatched precision, while maximising factory process efficiency.

Challenge:

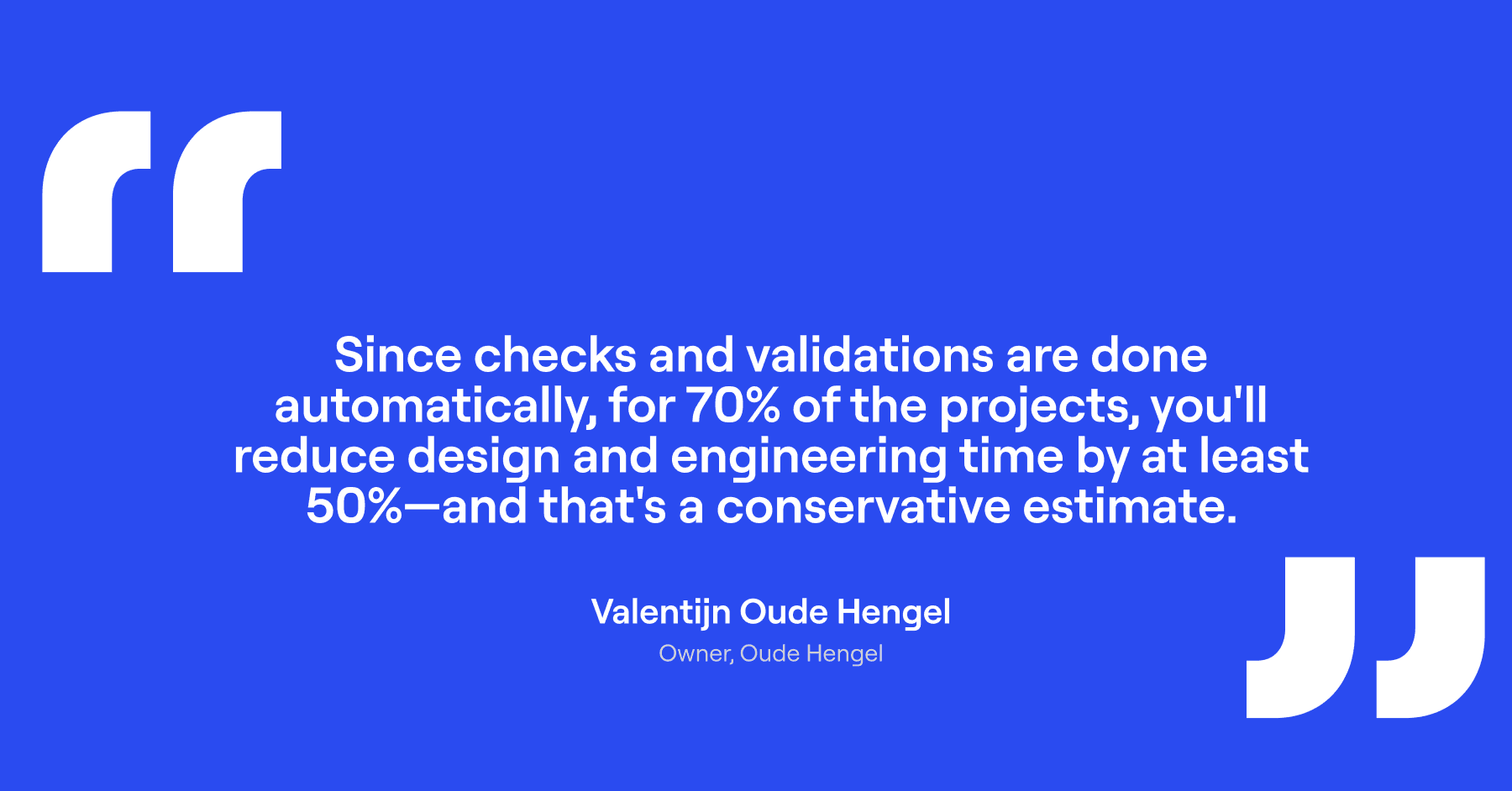

Oude Hengel grows due to an innovation mindset. They were the first in their region to bring in CNC machines, develop processes for the factory to become energy-neutral. But as demand grows, so does the need for faster design-to-production workflows. Traditionally, creating timber structures involved lengthy, manual processes with significant back-and-forth between customers and engineers.

Packhunt for Factories offered something that seemed impossible: making technically correct drawings in minutes, avoiding mistakes in delivering exactly what the client wants, and cutting the process from days to minutes.

Hear Valentijn Oude Hengel comment on how Packhunt for Factories changed their order-to-production process:

Solution: Transforming Timber Construction with Packhunt for Factories

Packhunt for Factories delivered a comprehensive configurator that allowed Oude Hengel to shift from traditional, manual design processes to a fully automated configure-to-order workflow. The configurator, embedded directly into their website, empowers Oude Hengel to generate technically correct designs in minutes, drastically reducing errors and providing clients with exactly what they need—faster than ever before.

The solution integrates parametric design models, digitizing Oude Hengel’s timber construction expertise and automating critical aspects of their operations. Key features of the configurator include:

BOM (Bill of Materials) and price calculations

Instant quote generation

In-house sales configurator for streamlined internal processes

Embedded configurator for customer-facing use on their website, enabling clients to configure their own projects

Future integration with CRM systems for seamless client management

Automated structural reports to ensure technical accuracy and compliance (future implementation)

Link to Tekla for enhanced structural modeling and engineering collaboration (future implementation)

This automation replaced the time-consuming, manual workflows that had previously been required. The configurator now enables Oude Hengel’s sales and engineering teams to handle up to 80% of designs with precision and speed. Customers can configure projects online, get real-time pricing, and receive production-ready drawings within minutes. This transformation has led to faster turnaround times, more efficient production workflows, and improved overall customer experience.

“We’re working with technical people (Packhunt for Factories) who can get the result that we want, and it’s going really fast. I didn’t expect it to be ready that fast.” - says Valentijn.

Want a personalized advice on how to streamline your factory processes?

Implementation: Shoulder-to-shoulder Path to Innovation

The collaboration between Packhunt for Factories and Oude Hengel began at a Bouwbeurs fair, where both teams aligned on a shared vision of digitizing timber construction from sales to production. Valentijn, initially sceptical, quickly recognized the potential of Packhunt’s digital solution.

The implementation process was carried out in bi-weekly workshops, where both teams worked shoulder to shoulder. These workshops allowed the Packhunt team to refine the configurator, ensuring it fits seamlessly into Oude Hengel’s workflow. The step-by-step approach helped align the product logic with Oude Hengel’s specific needs, transforming the system into the backbone of their sales and production operations.

With each iteration, the configurator improved, automating the generation of production-ready drawings and quotes, and reducing the need for manual inputs. What once took days now takes only minutes, significantly increasing efficiency and reducing errors.

Result: Fast, Efficient, and Error-Free Timber Factory

With Packhunt, Oude Hengel achieved remarkable results:

Design Turnaround: What took half a day now takes 3 minutes.

Productivity Boost: Their streamlined workflow has significantly increased production and sales.

Cost Savings: The automated workflow led to fewer errors and improved project efficiency, resulting in cost reductions.

Scalable Sales Process: The configurator enables seamless interactions between customers and Oude Hengel, allowing the company to sell their buildings more effectively, even outside working hours.

Flawless Execution: Automated design and structural reports ensure precise designs and error-free production, laying the groundwork for future expansions.

“You change the dimensions of the timber building, which instantly generates technical drawings, and you’re ready for production in 3 minutes. It’s almost too good to be true!” - Valentijn Oude Hengel.

Conclusion: Digitize to Lead. The Future of Timber Construction

Oude Hengel’s partnership with Packhunt for Factories is setting a new step in this company’s history of innovation. By fully embracing digitization with Packhunt for Factories, they have not only preserved their rich tradition but also positioned themselves for scalable future growth. Faster, more accurate, and ready to take on any challenge, Oude Hengel is leading the way in timber construction with the power of configure-to-order solutions.

What is Packhunt for Factories?

Packhunt for Factories is the backbone of a digital factory, with a parametric 3D web configurator and Inside Sales Configurator at the core of it. It is a system that helps manufacturers and suppliers to the building industry streamline the entire configure-to-production process.

Packhunt for Factories is implemented by automating product logic and customer journey to sell, design, engineer, produce, assemble and organise the logistics of (assembled) products. It has proven to digitally transform the sales processes, automate the workload and shorten sales, design and engineering tasks for our customers from weeks to minutes.